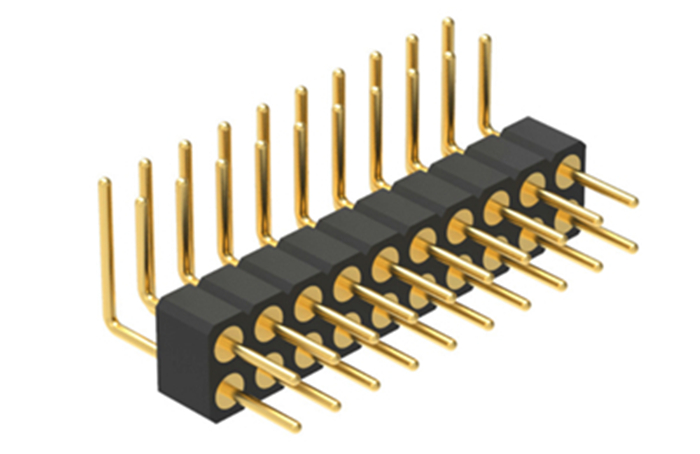

Machined pins for I/O and power connections: Precision Connectors for Electronic Assemblies

What are Machined Pins?

Machined pins are cylindrical shafts that are manufactured by turning, grinding, or milling a solid piece of material, typically metal or high-strength plastic. They are designed to fit into pre-drilled holes with exacting tolerances, ensuring a tight and secure fit. These pins are used to align and join components, transferring loads between parts and providing stability.

The machined contact is to develop individual solutions for special contact requirements in precisely application for the customer. The pin contact is precision machining pin components,recover machined Male pin,machined Socket pin,Press-Fit PCB Pins,machined Solder Cup Terminal Pins,Surface Mount PCB Pins and Screw Machined Pin.

Applications of Machined Pins

Machined pins find their place in a wide array of applications due to their strength and precision. They are commonly used in:

Aerospace: For joining aircraft components where lightweight and high strength are crucial.

Automotive: In engine assemblies, transmissions, and chassis construction for durability and reliability.

Industrial Machinery: To align and secure moving parts in machinery for consistent operation.

Construction: In structural assemblies for buildings and bridges to ensure stability and safety.

Manufacturing Process

The manufacturing of machined dowel pins involves several key steps:

Material Selection: High-quality materials like steel, stainless steel, or brass are chosen for their strength and resistance to wear.

Cutting and Shaping: The material is cut and shaped into the desired pin dimensions using lathes and mills.

Grinding and Polishing: To achieve a smooth surface and precise size, the pins are ground and polished.

Heat Treatment: Many dowel pins undergo heat treatment to enhance their mechanical properties, such as hardness and tensile strength.

Inspection and Testing: Each pin is inspected for dimensional accuracy and tested for material integrity to meet the required specifications.

Advantages of Machined Pins Contact

The advantages of using machined dowel pins are numerous:

Precision: They are machined to tight tolerances, ensuring a perfect fit in high-precision assemblies.

Strength: Made from strong materials, they can withstand high loads and stresses.

Reliability: Consistent performance in critical applications where failure is not an option.

Customizability: Tailored to specific application needs in terms of material, size, and finish.

Key Words:machined pins for I/O and power connections

,pcb pin,precision machining pin components,

gold plating machined pins,high current power pins,machined Crimp Pins and Receptacles,solder cup machined terminal pins